fluid control equipment range

PCI ProductsPCI successfully supplies a wide range of fluid control products within Sub-Saharan Africa. These include: South Africa, Zambia, Zimbabwe, Angola, DRC, Madagascar & Tanzania, amongst others.

Equipment to suit your

Process Control Requirements

We work with customers across the process industry and our dedicated and flexible approach, combined with local and international foot print ensures that we are able to satisfy our customer’s varying requirements.

Pumps

Pump & Motor Solutions designed for optimal performance, long service-life and durability.

Mechanical Seals

Our wide range of mechanical seals provide reliable, top quality solutions for your unique requirements.

Valves

Sourced from our world wide network to satify your shut down and installation schedules.

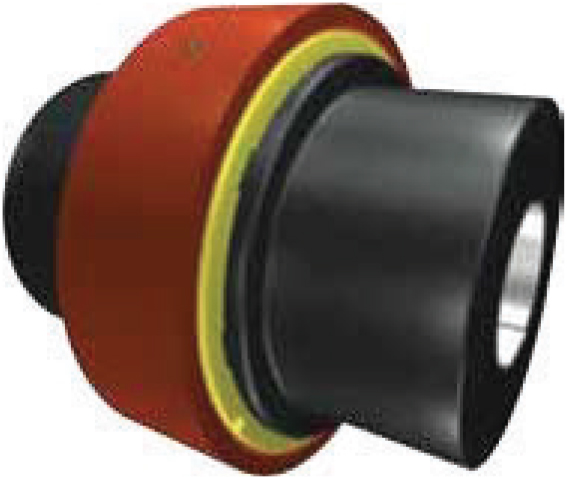

Rubber Bellows

PCI rubber expansion joints exceed industry standards & empowers your process systems. Stock availability through PCI.

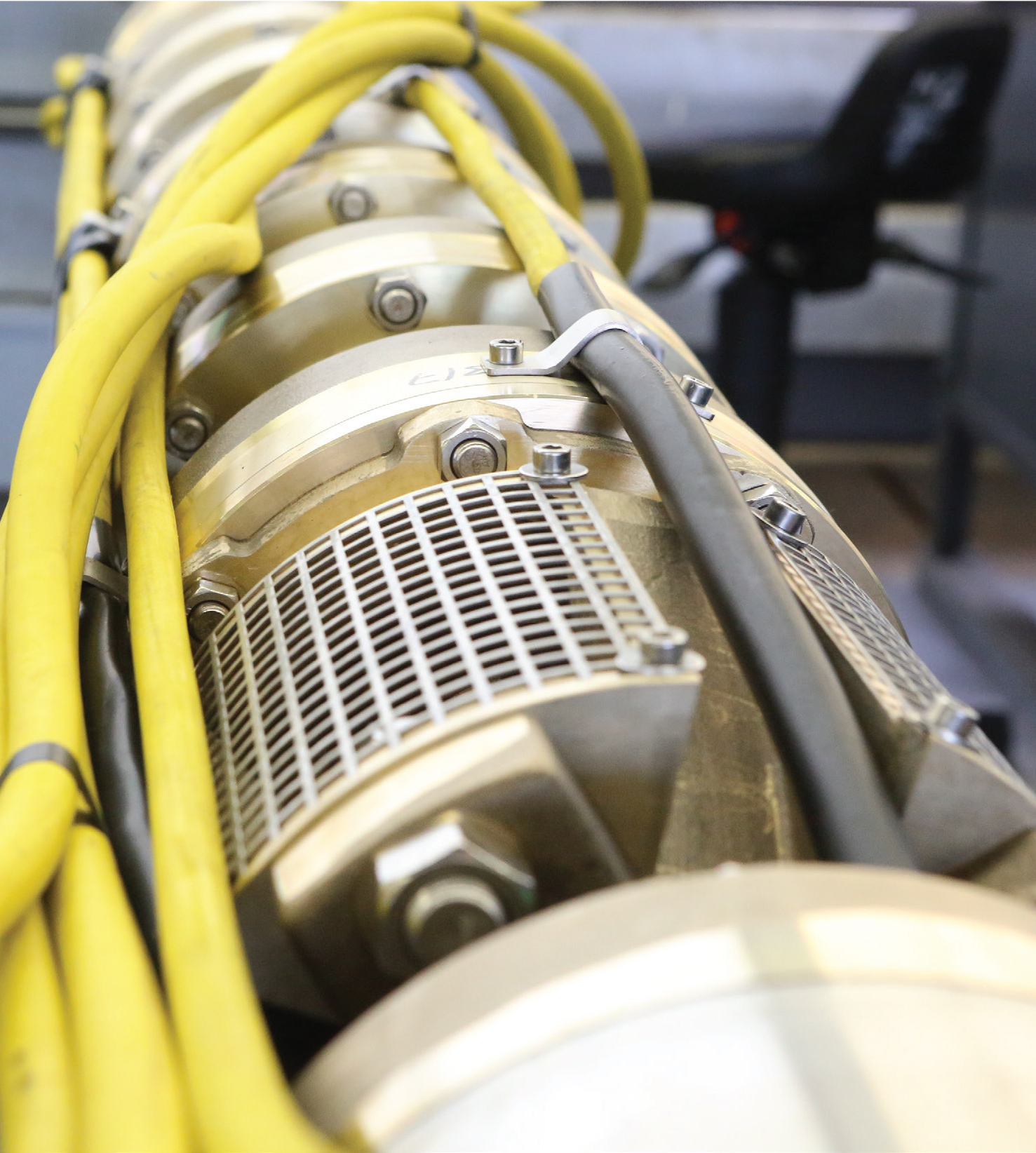

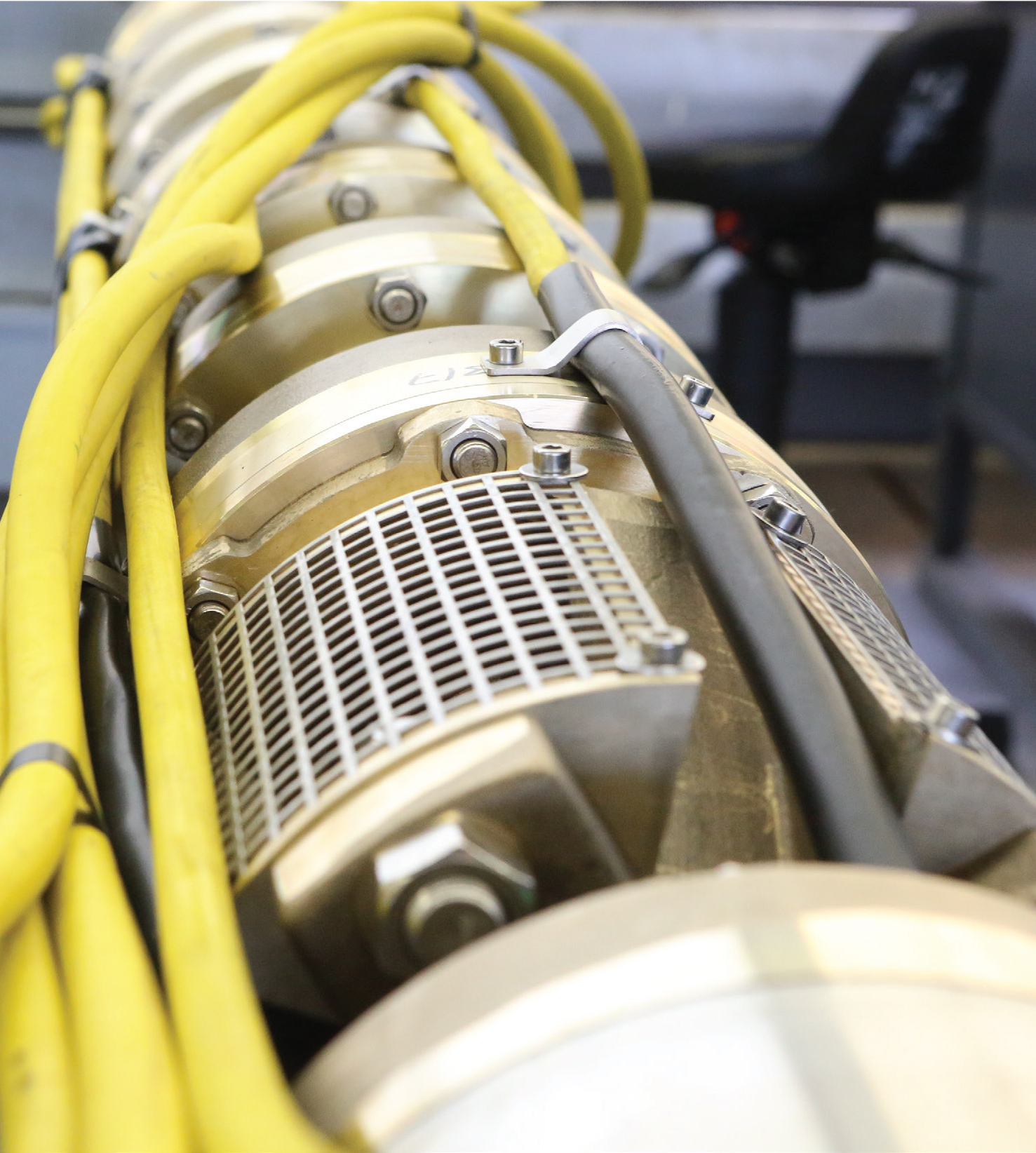

PUMP RANGE

Best-in-class submersible pump and motor solutions.

Companies’ worldwide use Pleuger’s submersible pumps in multiple applications within the water, marine and offshore, oil and gas and mining industries. Thousands of ships and platforms apply Pleuger Industries’ pumps and maneuvering systems.

| Pump Specifications | |

| 4″ to 50″ ø Single-stage / Multi-stage Flows to: 8000 m3/h / 35,223 gpm (Axial flows to 20,000 rn3/h 88,057 gpm) Heads to: 800 m / 2,625 ft Temperatures (Standard): -30 o c to 50 oc / -22 O F to 122 O F Temperatures (on request): -25 o c and 950C / -13 and 203 O F Higher temperatures on request Depth up to: 4000 m/ 13,123 ft (Deeper on request) |

|

| Pump Types | |

| Deep Well | Booster | Cavern | Bottom Intake | Flood | |

| Key Features | |

| Highly efficient hydraulics: | Flood-proof |

| Maintenance-free: | Safe against freezing |

| Built for reliability: | Reduced noise and vibration |

| Cost-effective lifecycle: | Range of material grades |

| Drinking water safe: | Optional installation accessories |

| Space efficient installation in wells: | Optional permanent magnet motor (PMM) technology |

| Standard Motors | |

| 6″ to 50″ Induction motor, Asynchronous motor Power output: 0.37 kW to 5 MW (0.5 HP to 6,705 HP) Operating speed: 200 to 3600 rpm — 2,4,6 pole designs 200 V to 6.6 kV (11 kV on request) / 50 and 60 Hz |

|

| Permanent Magnet Motors | |

| 6″ to 8″ ø Synchronous motor Power output: 4.0 to 200 kW (5.36 HP to 268 HP) Operating speed: 2100 to 3600 rpm (max 3800 rpm) 4 pole design Driven by Variable Frequency Drive (VFD) VFD input voltage 400 to 500 V / 70 and 120 Hz |

|

| Key Features | |

| Highly efficient motors: | Suitable for VFD operation |

| Standard and engineered options: | Operating temperature: |

| Standard water-filled motors: | Standard 50 ‘C |

| On request: oil filled motors: | On request: 95’C |

| Pump Specifications | |

| 4″ to 50″ ø Single-stage / Multi-stage Flows to: 8000 m3/h / 35,223 gpm (Axial flows to 20,000 rn3/h 88,057 gpm) Heads to: 800 m / 2,625 ft Temperatures (Standard): -30 o c to 50 oc / -22 O F to 122 O F Temperatures (on request): -25 o c and 950C / -13 and 203 O F Higher temperatures on request Depth up to: 4000 m/ 13,123 ft (Deeper on request) |

|

| Pump Types | |

| Deep Well | Booster | Cavern | Bottom Intake | Flood | |

| Key Features | |

| Highly efficient hydraulics: | Flood-proof |

| Maintenance-free: | Safe against freezing |

| Built for reliability: | Reduced noise and vibration |

| Cost-effective lifecycle: | Range of material grades |

| Drinking water safe: | Optional installation accessories |

| Space efficient installation in wells: | Optional permanent magnet motor (PMM) technology |

| Standard Motors | |

| 6″ to 50″ Induction motor, Asynchronous motor Power output: 0.37 kW to 5 MW (0.5 HP to 6,705 HP) Operating speed: 200 to 3600 rpm — 2,4,6 pole designs 200 V to 6.6 kV (11 kV on request) / 50 and 60 Hz |

|

| Permanent Magnet Motors | |

| 6″ to 8″ ø Synchronous motor Power output: 4.0 to 200 kW (5.36 HP to 268 HP) Operating speed: 2100 to 3600 rpm (max 3800 rpm) 4 pole design Driven by Variable Frequency Drive (VFD) VFD input voltage 400 to 500 V / 70 and 120 Hz |

|

| Key Features | |

| Highly efficient motors: | Suitable for VFD operation |

| Standard and engineered options: | Operating temperature: |

| Standard water-filled motors: | Standard 50 ‘C |

| On request: oil filled motors: | On request: 95’C |

Your Leading Specialists In

Process Containment

Hippo Slurry Pump Range – Your ally in pumping corrosive & acidic slurries

The Hippo slurry pump range was designed and developed to meet the harsh and continuous conditions set by the mining and mineral processing industries found in Southern Africa.

Creating a slurry pump range that is capable of running dry and operate in a wide variety of temperatures the Hippo Pump range is the ideal solution for dealing with high volume dewatering situation to harsh and abrasive applications; with a custom build solution for each application.

Submersible Top Suction

Bottom Suction Submersible

Bottom discharge slurry vertical spindle

Top Suction Slurry Vertical Spindle

Bottom Suction Slurry Verticle Spindle

Submersible Top Suction

Bottom Suction Submersible

Bottom discharge slurry vertical spindle

Top Suction Slurry Vertical Spindle

Bottom Suction Slurry Verticle Spindle

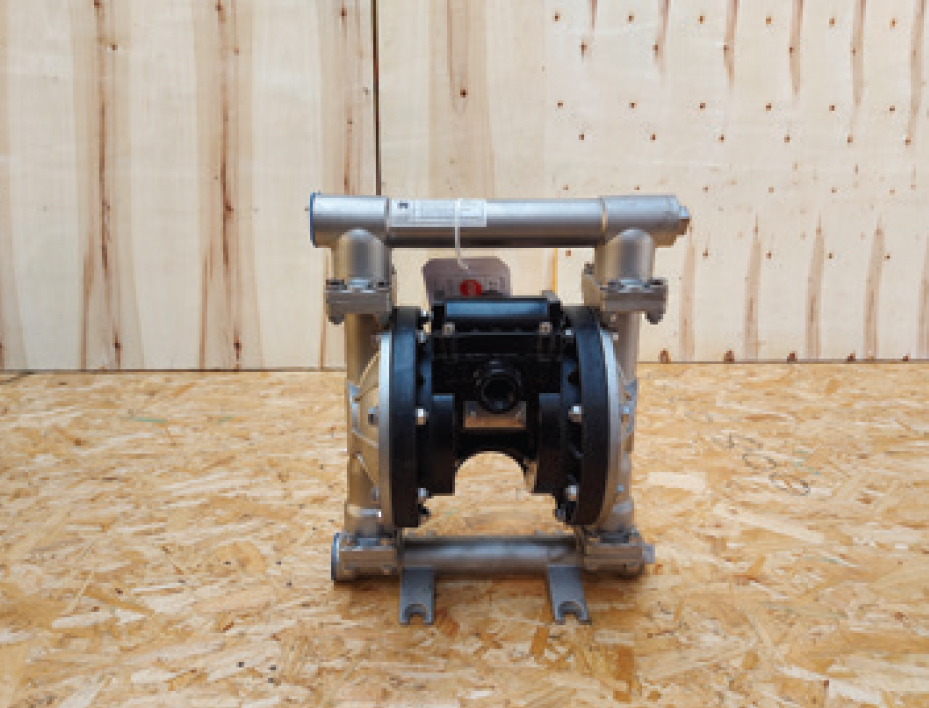

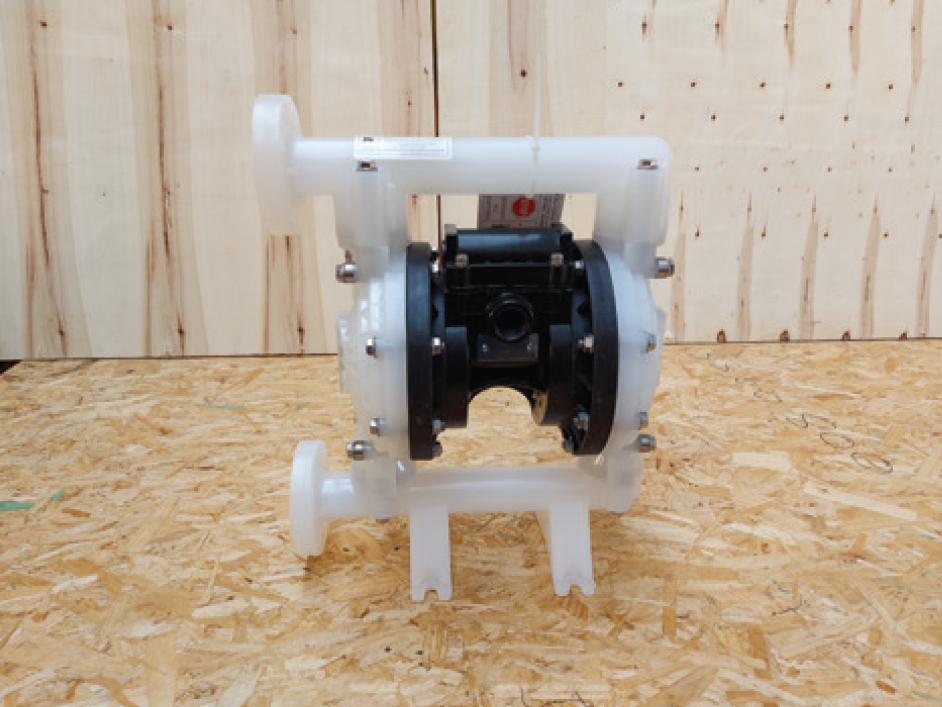

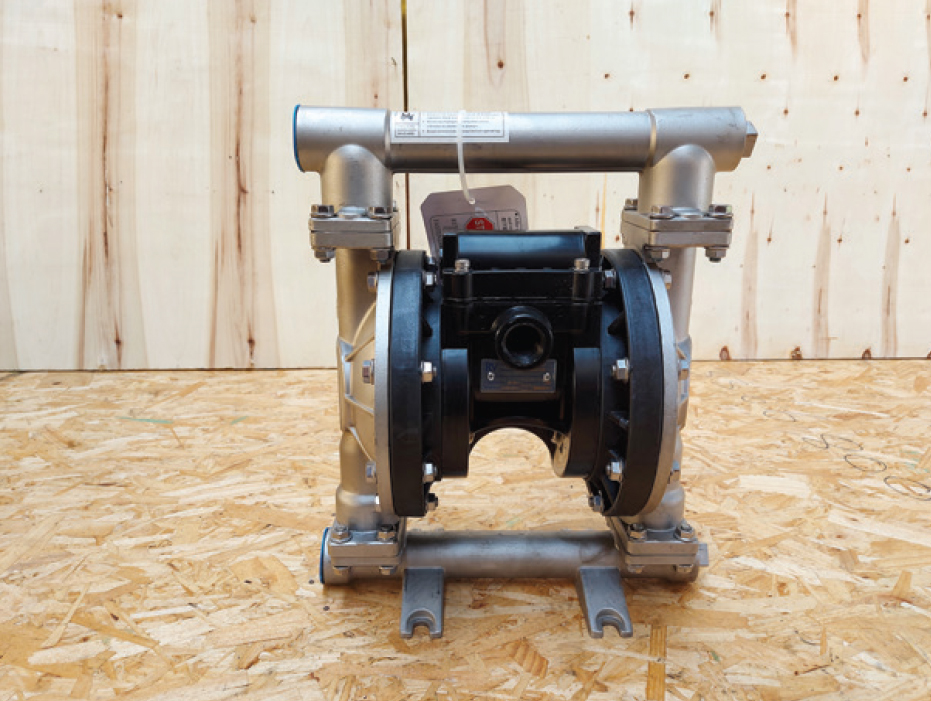

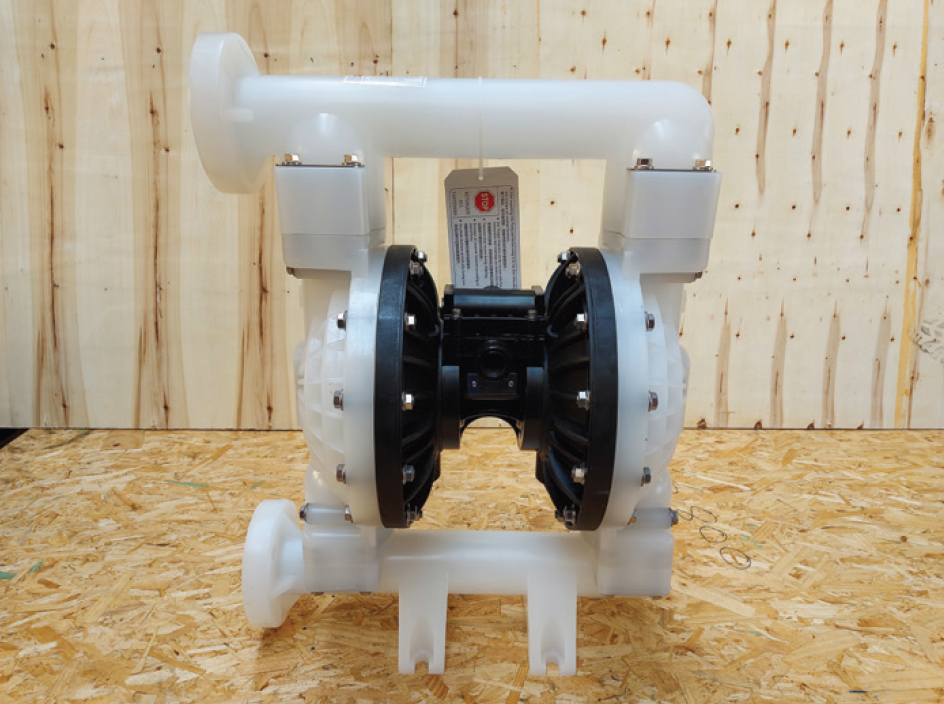

PCI Titan Pump Range – Diaphragm & Vacuum Pump Solutions

DIAPHRAGM PUMPS

PCS TITAN pumps are commonly used in industries where pumps would be required to operate without an operators continued attention, where there is a very real chance that the pump can run dry or where the air pump will need to handle slurries and sludges.

The simple and safe operation of air operated double diaphragm pumps with pneumatic control means that this pump is ideal for operating in zone one areas where there is demand for intrinsically safe operation. The pump is simply turned on or off by either closing the fluid discharge valve anywhere on the discharge line or by regulating the air supply.

TITAN Diaphragm Pump - Features

- Can run dry, without flow, for considerable periods of time without damage.

- Have good suction lift characteristics, typically up to 8 or even 9 meters at sea level.

- Excellent dry priming capability diaphragm pumps are capable of priming themselves from a dry start.

- Handle sludges and slurries with a relatively high amount of grit and solid content.

- Handle highly viscous liquids. A viscosity correction chart can be used as a tool to help prevent under-sizing AODD pumps.

- Available for industrial, chemical and hygienic applications from Stainless Steel to Polypropylene pumps PCS covers all your pump needs.

VACUUM PUMPS

TITAN Vacuum Pumps are 100% South African manufactured, built to suit the harshest conditions.

TITAN Vacuum Pump - Features

- Standard Materials of Construction include cast iron, bronze, 304 and 316 stainless steel (Exotic Materials can be arranged).

- TITAN Pumps have stuffing boxes built into the Casing Covers.

- Due to the lengthy service in the industry, modifications have been made to this range of pumps to improve the overall serviceability, which also ensures that TITAN Vacuum Pump wet-end spares are interchangeable with the majority of the vacuum pump population.

- High vacuum levels up to 25m Hg with the correct service liquid and cooling temperatures.

- Long service life, low maintenance costs.

- Minimal moving parts.

- Limited pulsation gas flow.

- Cooling water acts as lubrication internally.

- Liquid and vapour handling capabilities.

- Low starting torques.

- Variety of different service liquids available to be used.

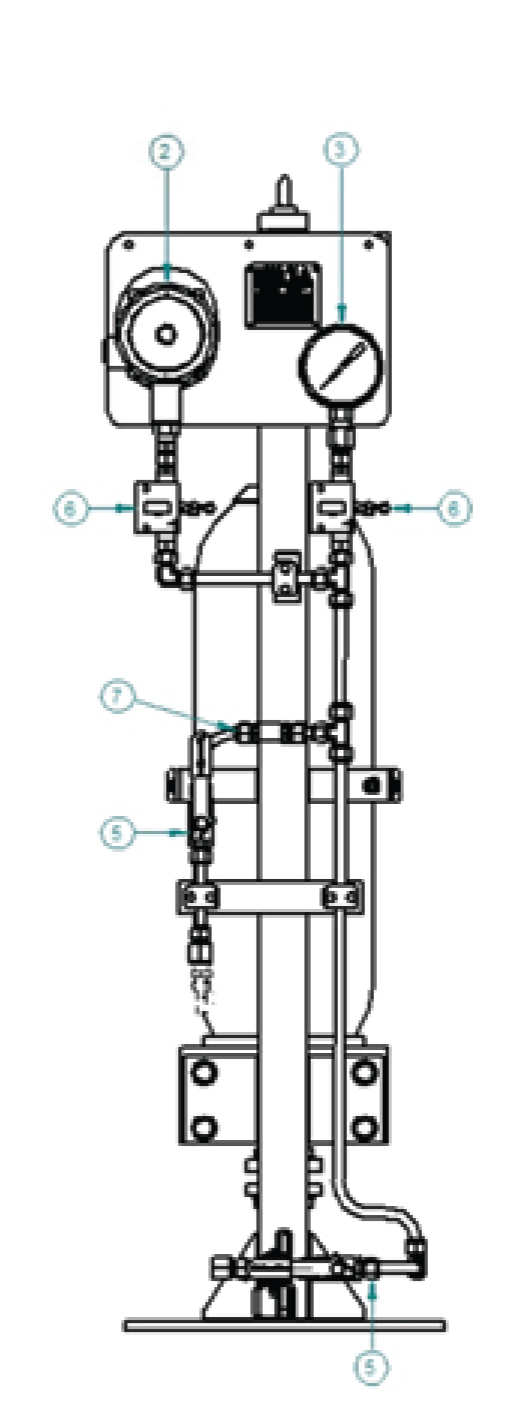

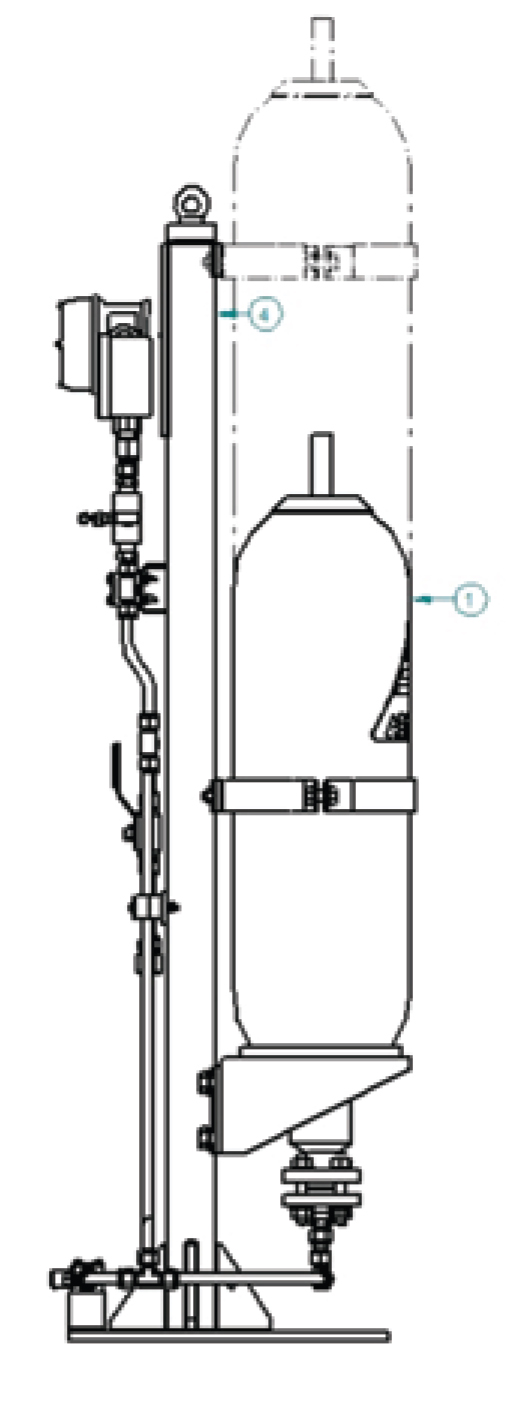

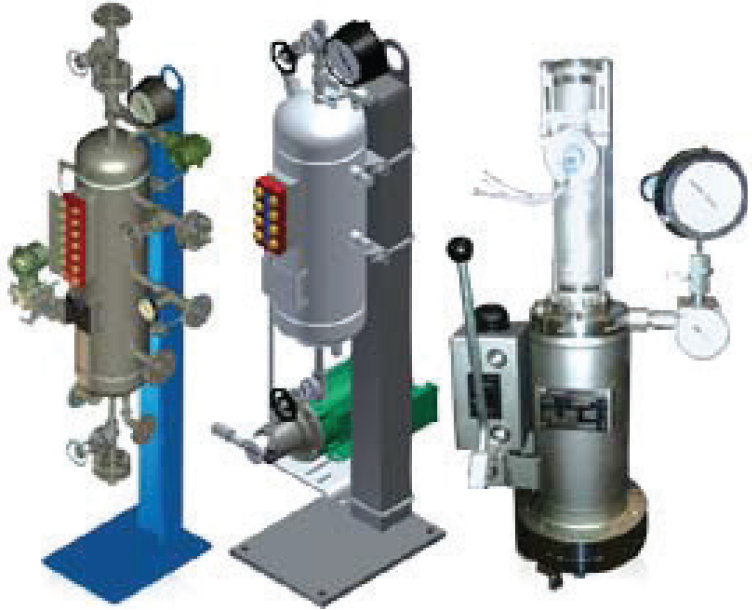

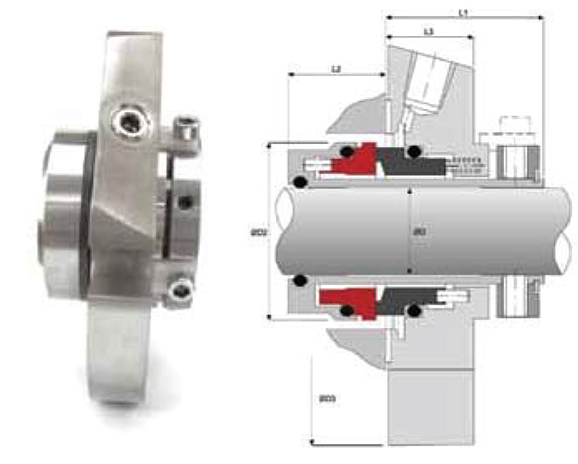

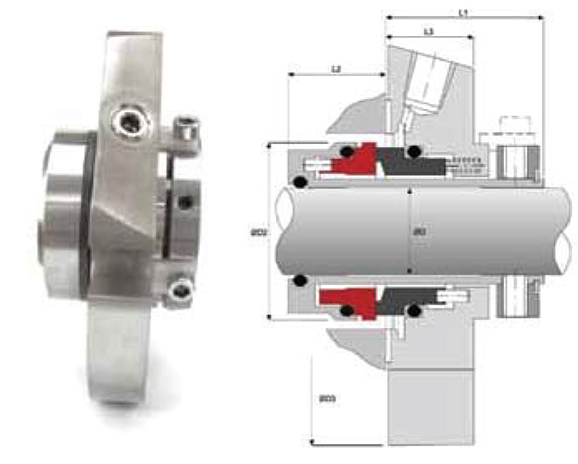

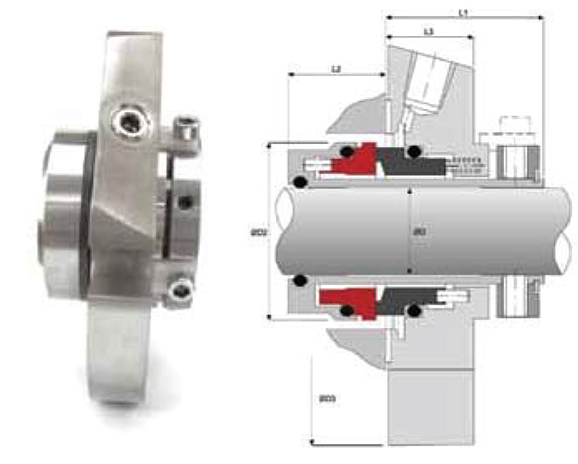

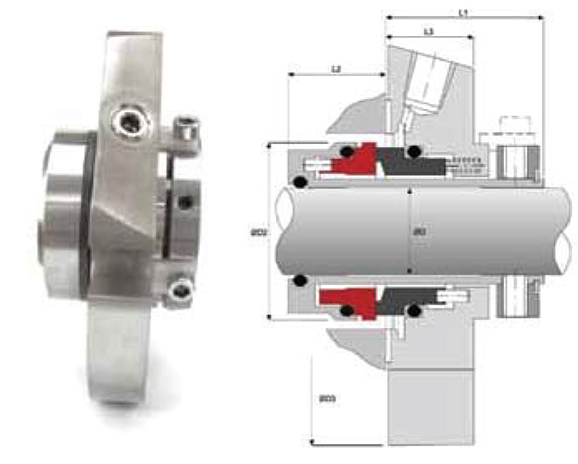

SEALING SYSTEMS

Roflex Sealing Systems - Features

- Cost effective compression fit alternative to the standard 53 system, designed to fulfil the need of the standardised flushing piping arrangement ’API Plan 52 & 53 systems’ as defined by API682/API610.

- For use in applications where barrier fluid contaminated by gas supplies is not acceptable.

- Barrier fluid circulation achieved by either the thermosiphon effect or through use of a seal pumping scroll.

- Commonly used in chemical, offshore and refining industries.

- Maximum assembly pressure (60 bar.) This is dependent on limits of individual components selected. Refer to the systems technical applications division for higher pressure applications.

- Utilises oil or water as barrier fluid.

- MADE IN SOUTH AFRICA

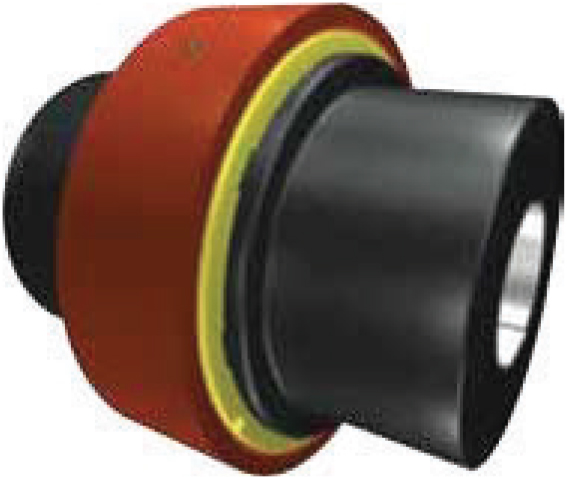

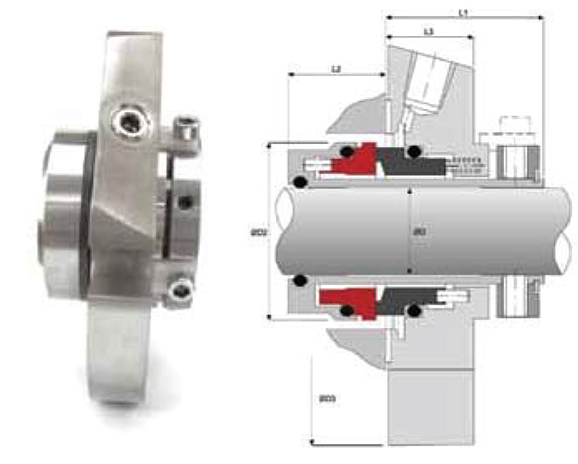

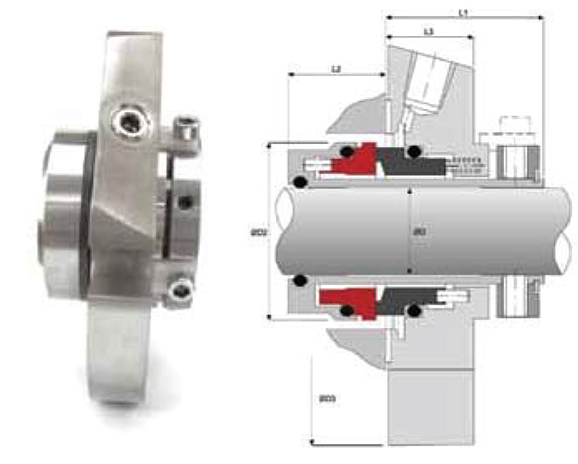

MECHANICAL SEALS

ELASTOMERIC

RFKS SERIES

(Transmission Couplings)

CARTRIDGE MECHANICAL SEALS

GLAND PACKING RANGE

Get In Touch With The PCI Team Today

Let us assit you with your process containment requirements

MECHANICAL SEALS

ELASTOMERIC

RFKS SERIES

(Transmission Couplings)

CARTRIDGE MECHANICAL SEALS

GLAND PACKING RANGE

Get In Touch With The PCI Team Today

Let us assit you with your process containment requirements

VALVES

PCI valve division is a focused service dedicated to supporting all aspects of valve supply and maintenance for the process industry.

Our valve division has three core elements:

- We engineer, source and supply mechanical, on off and control valves for clients, securing the shortest delivery time, competitive pricing and stringent quality standards.

- We have partnered with local and international manufacturing companies to design according to client specifics and also comply with international standards.

- We manage the integrity of our clients valve portfolio.

PCI valve division is a focused service dedicated to supporting all aspects of valve supply and maintenance for the process industry.

Our valve division has three core elements:

- We engineer, source and supply mechanical, on off and control valves for clients, securing the shortest delivery time, competitive pricing and stringent quality standards.

- We have partnered with local and international manufacturing companies to design according to client specifics and also comply with international standards.

- We manage the integrity of our clients valve portfolio.

PCI/ KIRA Valves & Engineering are fully equipped to refurbish most makes, types and sizes up to 3 meters of low, medium and high pressure valves.

Our premises consists of a valve refurbishing facility which consists of stripping, sandblasting, machining, welding, assembly, testing and spraying services.

Up to 90% of all valves can be refurbished at considerable saving when compare to purchasing a new unit.

-

Hard-faced satellite welding & high velocity oxy-fuel process is offered.

-

All grinding is offered

-

Reverse engineering by customer consent or OEM spares.

-

Options of NDT such as x-rays, dye-pen testing, UT testing, MPI & PMI are available.

-

Valves are pressure tested as per ASME B16.34, API 598 or BS Standards using test rigs with 1000 bar testing capabilities.

PCI/ KIRA Valves & Engineering are fully equipped to refurbish most makes, types and sizes up to 3 meters of low, medium and high pressure valves.

Our premises consists of a valve refurbishing facility which consists of stripping, sandblasting, machining, welding, assembly, testing and spraying services.

Up to 90% of all valves can be refurbished at considerable saving when compare to purchasing a new unit.

-

Hard-faced satellite welding & high velocity oxy-fuel process is offered.

-

All grinding is offered

-

Reverse engineering by customer consent or OEM spares.

-

Options of NDT such as x-rays, dye-pen testing, UT testing, MPI & PMI are available.

-

Valves are pressure tested as per ASME B16.34, API 598 or BS Standards using test rigs with 1000 bar testing capabilities.

PCI valve division is a focused service dedicated to supporting all aspects of valve supply and maintenance for the process industry.

Our valve division has three core elements:

- We engineer, source and supply mechanical, on off and control valves for clients, securing the shortest delivery time, competitive pricing and stringent quality standards.

- We have partnered with local and international manufacturing companies to design according to client specifics and also comply with international standards.

- We manage the integrity of our clients valve portfolio.

PCI/ KIRA Valves & Engineering are fully equipped to refurbish most makes, types and sizes up to 3 meters of low, medium and high pressure valves.

Our premises consists of a valve refurbishing facility which consists of stripping, sandblasting, machining, welding, assembly, testing and spraying services.

Up to 90% of all valves can be refurbished at considerable saving when compare to purchasing a new unit.

-

Hard-faced satellite welding & high velocity oxy-fuel process is offered.

-

All grinding is offered

-

Reverse engineering by customer consent or OEM spares.

-

Options of NDT such as x-rays, dye-pen testing, UT testing, MPI & PMI are available.

-

Valves are pressure tested as per ASME B16.34, API 598 or BS Standards using test rigs with 1000 bar testing capabilities.

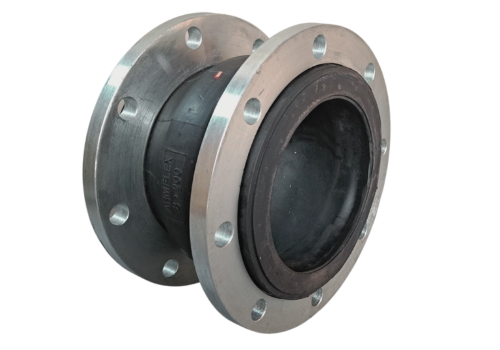

Rubber Bellows

In the fast-paced world of fluid control, precision, reliability, and durability are non-negotiable.

You’ve arrived at the destination where these crucial elements converge – Process Containment International, your premier supplier of top-quality rubber expansion joints designed to elevate your fluid control processes to new heights.

Precision Engineering: Our rubber expansion joints are the result of meticulous engineering, ensuring a perfect fit for your fluid control systems. This precision guarantees minimal leaks, reduced maintenance, and optimal system performance.

Unmatched Durability: Built to withstand the most demanding industrial conditions, our expansion joints are constructed using high-quality rubber compounds that are resistant to corrosion, chemicals, and extreme temperatures. This longevity translates into cost savings and uninterrupted operations.

Enhanced Safety: Safety is paramount in fluid control, and our expansion joints are designed with this principle at the forefront. They absorb vibrations, reduce stress on pipelines, and minimize the risk of system failure, safeguarding both personnel and equipment.

Versatility Redefined: From standard sizes to customised configurations, PCI offers a wide range of rubber expansion joints to cater to your unique requirements. No matter the complexity of your fluid control system, we have the solution you need.

We understand that trust is the cornerstone of any successful partnership in the fluid control industry. Here are some reasons why PCI stands out as your trusted supplier:

Decades of Expertise: With decades of experience serving the industry, our team of experts possesses in-depth knowledge of fluid control dynamics. We’re dedicated to delivering solutions that optimise your operations.

Quality Assurance: Our expansion joints undergo rigorous quality control processes to ensure they not only meet but exceed industry standards. We stand behind the quality of our products with pride.

Customer-Centric Approach: Your satisfaction is our top priority. We’re not just selling expansion joints; we’re providing solutions tailored to your success. Our responsive customer support team is here to assist you every step of the way.

Competitive Pricing: We believe that premium quality should be accessible. Our competitive pricing ensures you receive the best value for your investment.

Stock Availability: Our commitment to maintaining substantial stock levels means that you’ll have access to the expansion joints you need when you need them. We understand the value of timely delivery to keep your operations running smoothly.

Precision Engineering: Our rubber expansion joints are the result of meticulous engineering, ensuring a perfect fit for your fluid control systems. This precision guarantees minimal leaks, reduced maintenance, and optimal system performance.

Unmatched Durability: Built to withstand the most demanding industrial conditions, our expansion joints are constructed using high-quality rubber compounds that are resistant to corrosion, chemicals, and extreme temperatures. This longevity translates into cost savings and uninterrupted operations.

Enhanced Safety: Safety is paramount in fluid control, and our expansion joints are designed with this principle at the forefront. They absorb vibrations, reduce stress on pipelines, and minimize the risk of system failure, safeguarding both personnel and equipment.

Versatility Redefined: From standard sizes to customised configurations, PCI offers a wide range of rubber expansion joints to cater to your unique requirements. No matter the complexity of your fluid control system, we have the solution you need.

We understand that trust is the cornerstone of any successful partnership in the fluid control industry. Here are some reasons why PCI stands out as your trusted supplier:

Decades of Expertise: With decades of experience serving the industry, our team of experts possesses in-depth knowledge of fluid control dynamics. We’re dedicated to delivering solutions that optimise your operations.

Quality Assurance: Our expansion joints undergo rigorous quality control processes to ensure they not only meet but exceed industry standards. We stand behind the quality of our products with pride.

Customer-Centric Approach: Your satisfaction is our top priority. We’re not just selling expansion joints; we’re providing solutions tailored to your success. Our responsive customer support team is here to assist you every step of the way.

Competitive Pricing: We believe that premium quality should be accessible. Our competitive pricing ensures you receive the best value for your investment.

Stock Availability: Our commitment to maintaining substantial stock levels means that you’ll have access to the expansion joints you need when you need them. We understand the value of timely delivery to keep your operations running smoothly.

In the fast-paced world of fluid control, precision, reliability, and durability are non-negotiable.

You’ve arrived at the destination where these crucial elements converge – Process Containment International, your premier supplier of top-quality rubber expansion joints designed to elevate your fluid control processes to new heights.

Precision Engineering: Our rubber expansion joints are the result of meticulous engineering, ensuring a perfect fit for your fluid control systems. This precision guarantees minimal leaks, reduced maintenance, and optimal system performance.

Unmatched Durability: Built to withstand the most demanding industrial conditions, our expansion joints are constructed using high-quality rubber compounds that are resistant to corrosion, chemicals, and extreme temperatures. This longevity translates into cost savings and uninterrupted operations.

Enhanced Safety: Safety is paramount in fluid control, and our expansion joints are designed with this principle at the forefront. They absorb vibrations, reduce stress on pipelines, and minimize the risk of system failure, safeguarding both personnel and equipment.

Versatility Redefined: From standard sizes to customised configurations, PCI offers a wide range of rubber expansion joints to cater to your unique requirements. No matter the complexity of your fluid control system, we have the solution you need.

We understand that trust is the cornerstone of any successful partnership in the fluid control industry. Here are some reasons why PCI stands out as your trusted supplier:

Decades of Expertise: With decades of experience serving the industry, our team of experts possesses in-depth knowledge of fluid control dynamics. We’re dedicated to delivering solutions that optimise your operations.

Quality Assurance: Our expansion joints undergo rigorous quality control processes to ensure they not only meet but exceed industry standards. We stand behind the quality of our products with pride.

Customer-Centric Approach: Your satisfaction is our top priority. We’re not just selling expansion joints; we’re providing solutions tailored to your success. Our responsive customer support team is here to assist you every step of the way.

Competitive Pricing: We believe that premium quality should be accessible. Our competitive pricing ensures you receive the best value for your investment.

Stock Availability: Our commitment to maintaining substantial stock levels means that you’ll have access to the expansion joints you need when you need them. We understand the value of timely delivery to keep your operations running smoothly.

Additional Products Available Through PCI

The PCI range of process containment rotating equipment and associated ancilliaries extends beyond what is listed above.

Our team further assists with the following product solutions:

Flexible Expansion Joints & Protective Covers

Fabric Expansion Joints

Safety Shields & Valve Covers

Removable & Reuseable Insulation Covers

Complete Skids

The PCI Range

Our Trusted Brands

Get In Touch With Us

+27 (0)79 625 8105

PROCESS CONTAINMENT INTERNATIONAL

Unit 2, 3 Kyalami Road, Westmead, Pinetown, 3610, KZN